Flare Systems

- Our team of engineers has developed more than 2,000 flare systems on a global scale for the last 40 years.

- With special attention to innovation and technology development, our engineers have taken care to collect flares that have failed for study and failure analysis. This has allowed our team to be at the forefront of the sector for many years. Today we have intellectual property and patented solutions that improve the performance of flare types available in the market.

- Our engineering team has actively contributed to the development of the International standards API 520, API 521 and API-Standard-531. Their publications are available on the web. In addition, they have been active members of technical committees of international operating companies such as Exxon Mobil and Saudi Aramco.

- Our incineration systems have exceeded the threshold of 99% hydrocarbon destruction, thus exceeding in environmental matters what is required by the Federal Regulatory Code of the USA, EPA 40 CFR.

Technologies and processes for the oil and energy industry

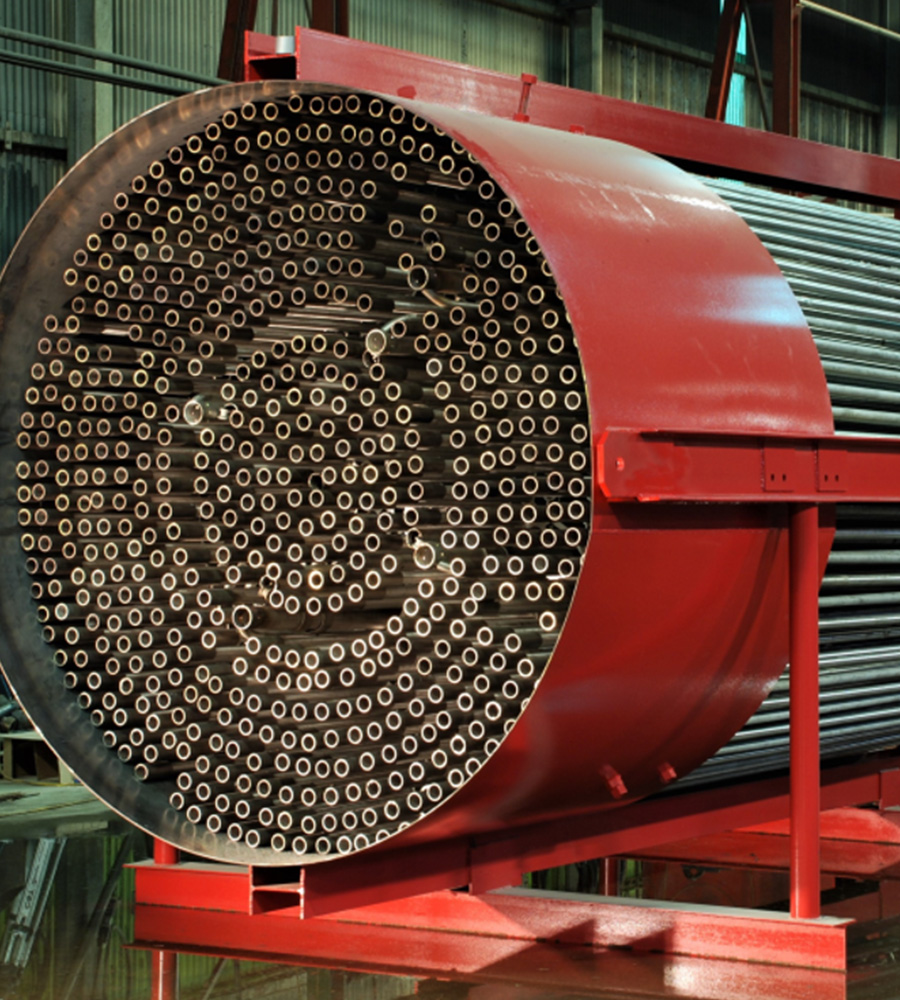

ENA Flares (Engineered Nozzle Array)

The ENA Flare model (Engineered Nozzle Array) is the result of over 40 years of design experience with multi tipped high pressure flares. It is designed to effectively apply high-pressure nozzle technology to flaring applications. The ENA model flares are engineered to offer superior combustion and flame control while providing outstanding service life.

- Design based on the principle of elimination of flame. Each end is a flame arrester in itself.

- Less exposure to the effects of the wind, as each tip has a maximum diameter of 1 “.

- Reduces the possibility of the tips collapsing.

- Improves the destruction of liquids and condensates.

- Reduces the average radiation.

- No moving parts.

- No welding at the top.

- Long service life.

Talk with Us

e-mail: info@marlandprocess.com

Phone: +1 (832) 815 4299